Poly Poly Core Spun®

Sewing Thread

Available Winding Type

Poly Poly Core Spun Sewing Thread

Sroduct Attributes

Color: raw white or dyed

Specifications: 16s/2/3, 28s/2/3, 45s/2/3, 60s/2/3, 70s/2/3, etc

Tube type: Loose tube

Materials: Polyester short fibers and long fibers

Package: Pp bags, cardboard boxes, and others

Customization: Specifications and packaging can be customized

Advantages: Suitable for special fields such as denim, clothing, furniture, bookbinding, sports industry, etc

Features: Suitable for high speed, automation, high efficiency, etc

Features

- High speed

- High return

- Excel in

- High efficiency

What's Poly Poly Core Spun® Polyester Sewing Thread ?

In some area it’s alias Poly-Wrapped Poly Core Thread, or Poly Poly Core Spun® sewing thread would be wildly known. The strength of the poly poly core spun® polyester sewing thread depends on the core wire, while the wear resistance and heat resistance depend on the covered yarn. Therefore, the core spun polyester sewing thread is suitable for high-speed sewing, as well as the need for higher sewing firm clothing.

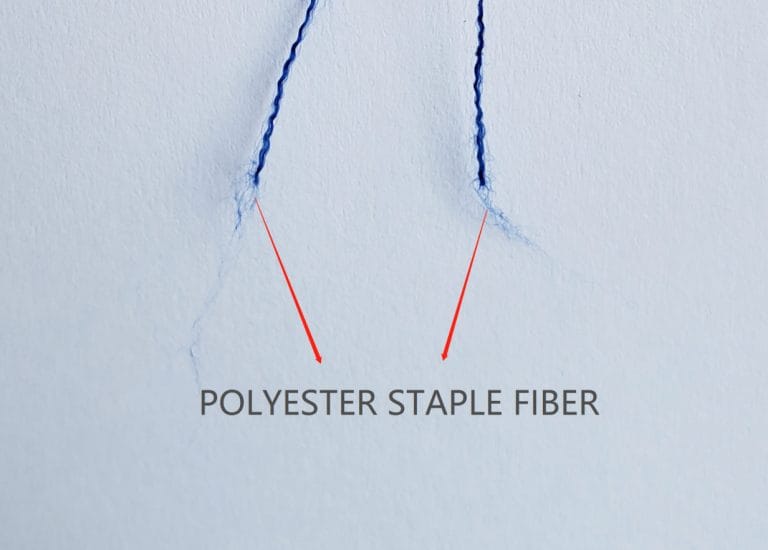

A polyester filament coated with polyester staple fiber during spinning, and then strands of these yarns are combined to make a thread.

Poly poly core spun sewing thread has both the high strength of polyester filament sewing thread and the natural fuzz and feel of polyester short fiber sewing thread or cotton thread, making it very suitable for high-speed sewing. To improve production efficiency, many garment companies use high-speed sewing machines that can reach speeds of over 5000 revolutions per minute. Ordinary spun polyester threads cannot withstand high heat or have insufficient tensile strength to break, so the most ideal sewing thread is to use poly poly core spun sewing thread.

Application: suits, shirts, denim, thin knit, suits, formal wear, industrial sewing, etc.

Structure of Core Spun Yarn.

First of all, our poly poly core spun® sewing thread is twisted by 2 or more single yarns which be called ” core spun yarn ” by TFO technical machine.

The mainly performance of strength depends on the core of the core spun yarn, it’s a kind of continuous fibre named filament. This core support high tenacity and low shrinkage speciality of polyester sewing thread. Over the core, there wraped with the short fibre, that makes the yarn has cotton’s looking and smooth touching.

Generally speaking, core spun yarn( thread) combined the advantage both of staple fibre and filament, which becomes more strength and easiliy using.

Contact us if you would like to know more about poly poly core spun®.

poly poly core spun® sewing thread - raw white

composition of 100% spun polyester yarn

poly poly core spun® sewing thread - material handling

Table

Construction:Poly Poly Core Spun Sewing Thread

Ne:70s/2

Tex:16

Tictet:220

Ndl Sz Min Sz:55/7

Ne:60s/2

Tex:18

Ticket:180

Ndl Sz Min Sz:55/7

Ne:50s/2

Tex:21

Tictet:140

Ndl Sz Min Sz:60/8

Ne:40s/2

Tex:30

Ticket:120

Ndl Sz Min Sz:60/8

Ne:45s/2

Tex:24

Tictet:120

Ndl Sz Min Sz:65/9

Ne:60s/3

Tex:27

Ticket:120

Ndl Sz Min Sz:65/9

Ne:36s/2

Tex:30

Tictet:100

Ndl Sz Min Sz:75/11

Ne:28s/2

Tex:40

Ticket:80

Ndl Sz Min Sz:90/14

Ne:20s/2

Tex:50

Tictet:60

Ndl Sz Min Sz:100/16

Ne:28s/3

Tex:60

Ticket:50

Ndl Sz Min Sz:100/16

Ne:16s/2

Tex:80

Tictet:40

Ndl Sz Min Sz:110/18

Ne:12s/2

Tex:105

Ticket:30

Ndl Sz Min Sz:120/20

Ne:16s/3

Tex:120

Tictet:25

Ndl Sz Min Sz:140/22

Ne:12s/3

Tex:135

Ticket:20

Ndl Sz Min Sz:180/24

Table

| Counts | Series | Recommended level | Applied to | TEX | Tkt | Useful | Feature |

| 20s/2 | SP CORE | Better | Face line | T-60 | 50 | Children’s wear cowboy | Reduce washing and repair |

| Twill pants | Higher tensile strength than staple polyester yarn. Good joint strength and wear resistance. Excellent colour fastness | ||||||

| Best | Face line | Recommended for automatic sewing machines (multidirectional). Good joint strength and wear resistance | |||||

| Work clothes | New sewing thread structure, high strength, good wear resistance. Reduce thread break and jumper during suture. The selection of polyester core wire can reduce the breakage caused by high speed seams. The excellent stitching effect is suitable for high-speed seams. | ||||||

| Casual wear (jacket) | New Sewing Thread structure with High strength. Reduce washing and repair. Reduce thread break and jumper during suture. The polyester core wire is selected to let the thread and the fabric fade synchronously in the washing process. Excellent stitching effect |

| Counts | Series | Recommended level | Applied to | TEX | Tkt | Useful | Feature |

| 28/2 | SP core | Better | Face/Bottom line | T-40 | 75 | The cowboy shirt | Superior sewing performance and thread safety. Excellent joint strength and wear resistance and excellent color fastness |

| Face line | Casual wear (jacket) | New Sewing Thread structure with High strength. Reduce washing and repair. Reduce thread break and jumper during suture. The polyester core wire is selected to let the thread and the fabric fade synchronously in the washing process. Excellent stitching effect | |||||

| Higher tensile strength than staple polyester yarn. Good joint strength and wear resistance. Excellent colour fastness | |||||||

| Home textile | Good joint strength and wear resistance | ||||||

| sportswear | Recommended for automatic sewing machines (multidirectional). Good joint strength and wear resistance | ||||||

| Best | overlocking stitch line | T-40 | 75 | Work clothes | New sewing thread structure, high strength, good wear resistance. Reduce thread break and jumper during suture. The selection of polyester core wire can reduce the breakage caused by high speed seams. The excellent stitching effect is suitable for high-speed seams. | ||

| Face/Bottom line | Casual wear (jacket) | ||||||

| New Sewing Thread structure with High strength. Reduce washing and repair. Reduce thread break and jumper during suture. The polyester core wire is selected to let the thread and the fabric fade synchronously in the washing process. Excellent stitching effect | |||||||

| Children’s wear cowboy The cowboy shirt | After washing, it has good effect of fading synchronously with fabric and good sewing property. | ||||||

| sportswear | Excellent shrinkage resistance prevents wrinkling during surface treatment and blanching | ||||||

| Home textile | Recommended for automatic sewing machines (multidirectional). Good joint strength and wear resistance | ||||||

| 28/3 | SP core | Best | Face line | T-40 | 75 | Children’s wear cowboy Twill pants | Recommended for automatic sewing machines (multidirectional). Good joint strength and wear resistance |

| Better | T-60 | 50 | Work clothes | Recommended for automatic sewing machines (multidirectional). Good joint strength and wear resistance The selection of polyester core wire can reduce the breakage caused by high-speed seams. The excellent stitching effect is suitable for high-speed seams. | |||

| Casual pants | The structure of the new sewing thread is water-resistant, which can reduce the repair after washing. Reduce thread break and jumper during suture. The polyester core wire is selected to let the thread and the fabric fade synchronously in the washing process. The excellent stitching effect is suitable for high-speed seams. Selection of chlorine-resistant sewing thread |

| Counts | Series | Recommended level | Applied to | TEX | Tkt | Useful | Feature |

| 40/2 | SP core | Better | Face/Bottom line | T-24 | 120 | Children’s clothing shirt | Recommended for automatic sewing machines (multidirectional). Good joint strength and wear resistance |

| Good | Face line | Down jacket | |||||

| Best | Bottom line | Children’s clothing Twill pants | |||||

| Face/Bottom line | Down jacket | Excellent shrinkage resistance prevents wrinkling during surface treatment and blanching The excellent resistance of sewing thread can be used to sew under low tension and reduce down-down outing. | |||||

| Children’s clothing shirt | Excellent shrinkage resistance prevents wrinkling during surface treatment and blanching |

| Counts | Series | Recommended level | Applied to | TEX | Tkt | Useful | Feature |

| 45/2 | SP core | Better | Face line | T-24 | 120 | sportswear, Shirt thread | Superior sewing performance and thread safety. Excellent joint strength and wear resistance and excellent color fastness |

| Best | Face/Bottom line | After washing, it has good effect of fading synchronously with fabric and good sewing property. | |||||

| Excellent shrinkage resistance prevents wrinkling during surface treatment and blanching | |||||||

| Face line | underwear | Excellent sewing performance and zero yield make high-quality underwear products of the first choice. Soft bottom line, close care, make underwear more comfortable |