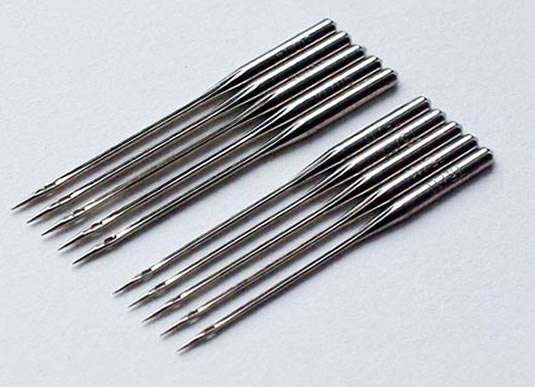

- Use a smaller diameter needle whenever possible. A smaller diameter needle will definitely minimize needle heat and may be the solution in marginal situations.

- Use a “ball eye” needle. A “ball eye” needle is where the diameter across the eye is generally larger than the blade diameter, therefore, it opens up a larger hole, minimizing the friction on the needle blade. Many needle manufacturers even have an “oversized ball eye” needle in some classes of needles that are commonly used for sewing heavy fabrics.

- On leather or other homogeneous fabrics, use a needle with cutting edges like a diamond, triangle, or wedge point. These needle point types actually cut through the fabric minimizing the penetration resistance and needle heat. Cutting point needles are not recommended for woven or knitted fabrics used for making apparel due to fabric damage.

- Try needles with special low friction surfaces. Most needles have a low friction chrome plating, however, there are other special needle coatings like Teflon or Tungsten that will minimize the friction between the needle and the fabric.

- Use needle coolers or devices that blow compressed air on the needle during sewing. This requires the availability of compressed air and lines carrying this air to the sewing machines. Machines should have control switches that conserve the consumption of compressed air and only supplies air on the needle during sewing.

- Ask you thread supplier if they have products available with heavier lube levels. The danger of using excessively high lube applications is finish migration in to the seam.

- Equip the machine with a needle positioner that positions the needle down after long high-speed runs. This allows the fabric to help dissipate heat and hopefully prevents the thread from melting; however, it can cause more needle holes on synthetic fabrics.

- Slow the sewing machines down to an acceptable level to minimize thread breakage due to needle heat.

Learn about the previous article: Reasons of the easily broken during stitching.