Thread breakage and skipped stitches are common aggravations on any sewing floor because it interrupts production, affects quality, and reduces the earnings and efficiency of production operators. Thread breakage and skipped stitches can be caused by many factors including:

- Wrong thread for the application.

- Quality defects in the thread.

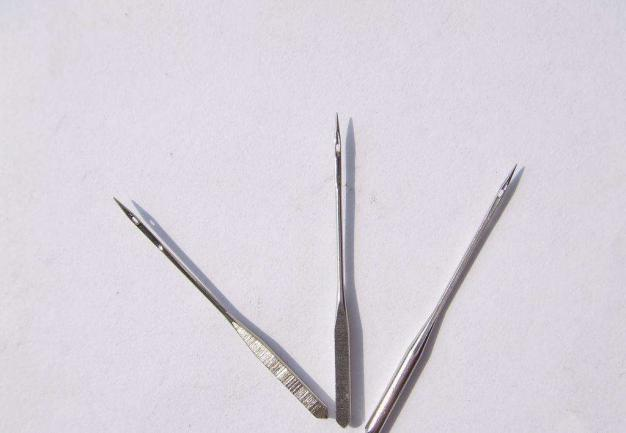

- Improper needle / thread size relationship.

- Worn or defective thread guides or eyelets.

- Improper threading.

- Excessive machine thread tension.

- Defective needle or improper positioning of the needle.

- Needle heat.

- Machines out of adjustment.

- Improper feeding.

- Improper operator handling.

As you can see then there are many variables that impact thread breakage and skipped stitches.